Products

We have a wide range of PVC Compounds for various industries. Please note that only some of the specifications have been tabled here and a lot more can be customized. All kind of customised modifications are possible.

Please click on the links below to see various options available:

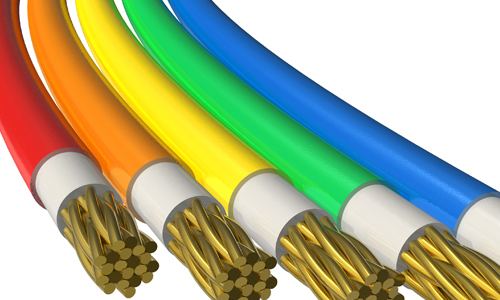

PVC Cable (Insulation)

We offer wide range of PVC compounds for wires and cables customised as per our client's requirements achieved by using plasticizers, stabilizers and modifiers in varying combinations. We use only high grade raw material so that the finished product is durable and of the highest quality.

| Grade | Variants | Action | ||||||

|---|---|---|---|---|---|---|---|---|

| Grade Name | Bp-09 | Bp-15 | Bp-04 | Bp-10FR | Bp-01 | Bp-25 | ||

| Grade Name As Per IS 5831 | Type A | Type A | Type A | Type A FR | Type B | Type C | ||

| Maximum Operating Temperature C | 70 | 70 | 70 | - | - | 85 | ||

| Properties of PVC Compound Gravity | 1.30(+/-0.02) | 1.40(+/-0.02) | 1.45(+/-0.02) | 1.50(+/-0.02) | 1.35(+/-0.02) | 1.33(+/-0.02) | ||

| Hardness Shore A | 88(+/-3) | 90(+/-3) | 90(+/-3) | 92(+/-3) | 94(+/-3) | 90(+/-3) | ||

| Thermal Stability @ 200°C | 110 | 125 | 110 | 130 | 150 | 110 | ||

| Volume Resistivity @ 27°C | 5 x 1013 | 1 x 1014 | 7 x 1013 | 7 x 1013 | 1 x 1014 | 1 x 1015 | ||

| Tensile Strength N/mm2 | 16 | 17 | 16 | 15 | 18 | 18 | ||

| Elogation At Break % | 250 | 250 | 250 | 230 | 180 | 200 | ||

| Ageing Temperature °C | 80 | 80 | 80 | 80 | 100 | 135 | ||

| Duration of Ageing, Hours | 168 | 168 | 168 | 168 | 168 | 168 | ||

| Variation of Tensile Strength % (+/-) | 20 | 20 | 20 | 20 | 25 | 25 | ||

| Variation of Elogation % (+/-) | 20 | 20 | 20 | 20 | 25 | 25 | ||

| Loss of Mass mg/cm2 | 2 | 2 | 2 | 2 | 2 | 2 | ||

| Oxygen Index (LOI) | - | - | - | 31 | - | - | ||

| Temperature Index °C Min. | - | - | - | 300 | - | - | ||

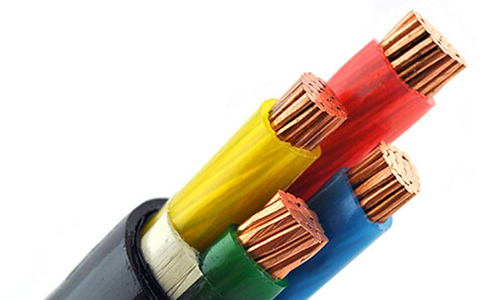

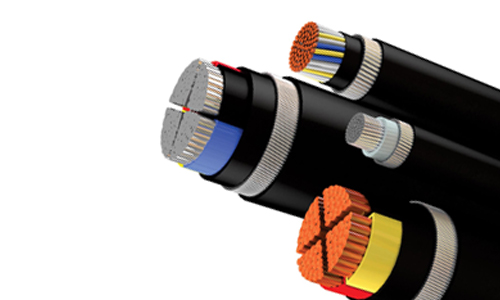

PVC Cable (Sheathing)

Our range of PVC compounds are used in cable industry for manufacture of protective wires and cable sheaths. We offer various degrees of modifications as required by our customers and the finished products are durable and conforms to the regulatory requirements.

| Grades | Variants | Action | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Grade Name | Bp-12 | Bp-16 | Bp-75 | Bp-06 | Bp-03 FR | Bp-02 | Bp-05 | Bp-04 FR | Bp-33 | ||

| Grade Name As Per IS 5831 | ST-1 | ST-1 | ST-1 | ST-1 | ST-1 FR | ST-2 | ST-2 | ST-2 FR | FRLS | ||

| Maximum Operating Temp. °C | 70 | 70 | 70 | 70 | 70 | 90 | 90 | 90 | 90 | ||

| Properties of PVC Compounds | |||||||||||

| Gravity | 1.35(+/-0.02) | 1.52(+/-0.02) | 1.43(+/-0.02) | 1.56(+/-0.02) | 1.50(+/-0.02) | 1.48(+/-0.02) | 1.52(+/-0.02) | 1.54(+/-0.02) | 1.54(+/-0.02) | ||

| Hardness Shore A | 75(+/-3) | 90(+/-3) | 85(+/-3) | 90(+/-3) | 90(+/-3) | 90(+/-3) | 92(+/-3) | 92(+/-3) | 92(+/-3) | ||

| Thermal Stability @ 200°C | 60 | 60 | 60 | 60 | 110 | 110 | 110 | 125 | 130 | ||

| Tensile Strength N/mm2 | 15 | 15 | 15 | 15 | 16 | 16 | 15 | 15 | 14 | ||

| Elogation At Break % | 250 | 280 | 230 | 200 | 220 | 220 | 200 | 220 | 200 | ||

| Ageing Temperature °C | 80 | 80 | 80 | 80 | 100 | 100 | 100 | 100 | 100 | ||

| Duration of Ageing hours | 168 | 168 | 168 | 168 | 168 | 168 | 168 | 168 | 168 | ||

| Variation of Tensile Strength % (+/-) | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | ||

| Variation of Elogation % (+/-) | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | ||

| Loss of Mass mg/cm2 max. | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | ||

| Additional Properties | |||||||||||

| Oxygen Index (LOI) | - | - | - | - | 30 | - | - | 31 | 32 | ||

| Temperature Index °C Min. | - | - | - | - | 280 | - | - | 290 | 300 | ||

| Smoke | - | - | - | - | - | - | - | - | 58 | ||

| HCL | - | - | - | - | - | - | - | - | 18 | ||

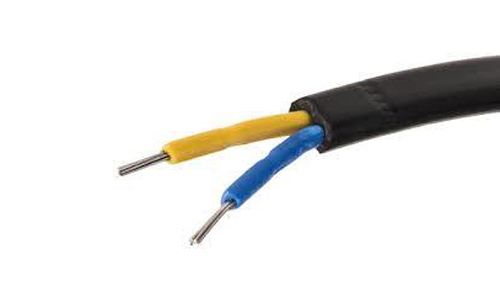

Automotive

Bansal Polyplast offers line of RoHS, Non-phthalate and REACH compliant PVC compounds useful for various application in the automotive wires industry, that conforms to the most stringent industry and regulatory standards.

| Colour | Specific Gravity | Tensile | E.B. | Hardness | Application | Action | |

|---|---|---|---|---|---|---|---|

| Black | 1.46(+/-0.03) | 110 min. | 200 min | 75(+/-3) | EXTRUSION | ||

| Black | 1.37(+/-0.03) | 140 min | 300 min | 80(+/-3) | EXTRUSION | ||

| Natural | 1.40(+/-0.03) | 100 min | 300 min | 65(+/-3) | EXTRUSION | ||

| TPT | 1.21(+/-0.03) | 100 min | 350 min | 65(+/-3) | EXTRUSION | ||

| TPT | 1.25(+/-0.03) | 150 min | 300 min | 90(+/-3) | EXTRUSION | ||

| Black | 1.42(+/-0.03) | 110 min. | 300 min | 75(+/-3) | EXTRUSION | ||

| Black | 1.32(+/-0.03) | 100 min | 350 min | 65(+/-3) | EXTRUSION | ||

| Black | 1.27(+/-0.03) | 100 min | 300 min | 70(+/-3) | EXTRUSION | ||

| Black | 1.43(+/-0.03) | 30 min | 350 min | 47(+/-3) | MOULDING | ||

| Black | 1.43(+/-0.03) | 50 min | 300 min | 60(+/-3) | MOULDING | ||

| Black | 1.46(+/-0.03) | 45 min | 300 min | 55(+/-3) | MOULDING | ||

| Black | 1.46(+/-0.03) | 45 min | 300 min | 60(+/-3) | MOULDING | ||

| Black | 1.51(+/-0.03) | 50 min | 300 min | 70(+/-3) | MOULDING | ||

| Black | 1.45(+/-0.03) | 50 min | 350 min | 50(+/-3) | MOULDING | ||

| Black | 1.32(+/-0.03) | 70 min | 250 min | 70(+/-3) | MOULDING | ||

| Black | 1.27(+/-0.03) | 50 min | 300 min | 55(+/-3) | MOULDING | ||

| Black | 1.30(+/-0.03) | 100 min | 300 min | 75(+/-3) | MOULDING | ||

| Black | 1.45(+/-0.03) | 90 min | 300 min | 75(+/-3) | MOULDING | ||

Footwear

PVC Footwear compounds available with us are super flexible, with different beautiful colors and hardness. This range can be used for manufacturing shoe soles & uppers. Abrasion resistance, oil resistance and smooth surface finish are added features of our products.

| Colour | Specific Gravity | Tensile | E.B. | Hardness | Application | Action | |

|---|---|---|---|---|---|---|---|

| Natural | 1.20(+/-0.03) | 100 min | 350 min | 55(+/-3) | MOULDING | ||

| Natural | 1.35(+/-0.03) | 120 min | 300 min | 75(+/-3) | MOULDING | ||

| Natural | 1.40(+/-0.03) | 80 min | 250 min | 70(+/-3) | MOULDING | ||

| Natural | 1.21(+/-0.03) | 110 min. | 325 min | 65(+/-3) | MOULDING | ||

P P Fillers

Polypropylene Filler is manufactured with tight process capability standards, ensuring high levels of consistency are met for your unique wire and cable needs.

Polypropylene tape cable filler is manufactured with a proprietary process that provides outstanding fill-per-unit weight, low cost and superb impact and crush resistance without the high capital costs and limited line speeds of extruded fillers. The filler is clear in color and fibrillated or serrated, allowing them to evenly fill cable free space, improving the aesthetics, robustness and marketability of your cables.

PVC Fillers

With rich industry experience we are able to offer optimal grade series of PVC Filler masterbatch that fulfills our client's demands. Our PVC Fillers are light weight, durable in nature and of top quality. These are manufactured as per market trends and conforming to highest quality standards.

PVC/HDPE Tapes

We offer to our clients, HDPE Tapes that conforms to the universally accepted standards and using approved fabric. Various modifications are available. The finished product is tear resistant, durable and of premium quality.

HDPE/LDPE Compounds

We offer HDPE compounds that has low degree of branching and has high tensile strength, useful for various applications like for products, packaging and toys manufacturing.

Our range of LDPE compounds are created with free-radical polymerization. High degree of branching with long chain will give molten LDPE unique and desirable flow properties.